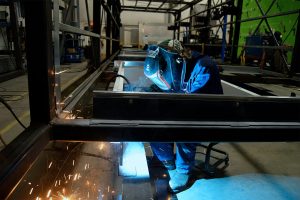

Welding is a manufacturing method that employs heat, pressure, or both to fuse two or more pieces, forming a joint when the parts cool. Welding is often utilized on metals and thermoplastics, but wood may also be welded. A weldment is a term used for the fully welded junction. Certain materials need the use of specific methods and techniques. Some materials are deemed “unweldable,” a phrase not generally found in dictionaries yet descriptive and valuable in engineering. The linked components are known as the foundation material. Filler or consumable describes the substance that is added to make the junction. Due to their form, these materials might be referred to as base plates or tubes, flux-cored wire, consumable electrodes (for arc welding), etc.

A weldment is a term used for a finished welded junction.

Welding is a manufacturing method in which two or more pieces are joined using heat, pressure, or a combination of the two to produce a joint while the parts cool. By the way, welding in Durango is often performed on metals and thermoplastics; wood may also be welded. A weldment is a term used for a finished welded junction.

How Does Welding Function?

Welding involves combining two materials without using a binder substance. In contrast to brazing and soldering, which use a binder with a lower melting point, welding directly unites two workpieces. Most modern welding comes into two categories: arc welding and torch welding. Arc welding uses an electrical arc to melt the work materials and a filler material (also referred to as the welding rod) to create the welds. Attaching a grounding wire to the welding material or another metal surface is required for arc welding. Another wire, an electrode lead, is put on the material to be welded. An electric arc is produced when the information is separated from the substance. It resembles the sparks produced while disconnecting jumper wires from an automobile battery. The turn then melts the workpieces and the filler material used to unite them.

SMAW, MIG, and TIG are all examples of arc welding.

These three overall strategies each have their pros and disadvantages. For example, stick welding is affordable and straightforward to learn. Additionally, it is slower and less adaptable than other approaches. In contrast, TIG welding is tough to master and needs a complex apparatus. However, TIG welding generates high-quality welds and can join materials that other techniques cannot. Torch welding is another common welding technique. Typically, an oxyacetylene torch is used to melt the working material and welding rod. The welder simultaneously controls the flame and rod, allowing them a great deal of control over the weld. While torch welding has become less widespread in the industrial sector, it is still often utilized in sculptures and for maintenance and repair work.

Varieties Of Welding

There are four primary welding techniques. MIG – Gas Metal Arc Welding (GMAW), TIG – Gas Tungsten Arc Welding (GTAW), Stick – Shielded Metal Arc Welding (SMAW), and Flux-cored – Flux-cored Arc Welding (FCAW) are the four most common welding processes (FCAW). Here, we examine each sort of welding in further detail. This is all about the varieties of welding in Durango.

- MIG WELDING Or GMAW

MIG welding is one of the most widespread methods of welding that novices must master. The car sector employs MIG welding to repair vehicle exhaust, as well as in the construction of homes and structures. This method of arc welding uses an electrode consisting of a continuous wire. Additionally, shielding gas goes through the welding gun to prevent contamination.

- TIG WELDING Or GTAW

TIG welding, like MIG, employs the arc, but it is one of the most challenging welding processes to master. TIG welding is performed using a tungsten electrode. Tungsten is among the most complex metallic substances. It does not disintegrate or burn away. For TIG welding, two hands are necessary. A TIG torch is held in one hand while the other steers the rod. This torch generates the heat and arc required for welding the majority of popular metals, including aluminum, steel, nickel alloys, copper alloys, cobalt, and titanium.